The NOAA Ship Nancy Foster (R 352) is a research vessel operated by the National Oceanic and Atmospheric Administration (NOAA). She was originally built as a Navy yard torpedo test craft at McDermott Shipyards in Amelia, Louisiana and launched in 1990. In 2001, the US Navy transferred the ship to NOAA.

The ship is named for Dr. Nancy Foster, who was the director of the National Marine Fisheries Service’s Office of Protected Resources for several years. The ship is 186 feet long with a beam of 40 feet. She has a total of 39 bunk spaces.

During the Winter of 2018, CMC was contracted by Detyens Shipyards, Inc. to perform several tasks during a 90 day availability, which included: performing a Deadweight Survey, Stability Test (Inclining Experiment), updating the ship’s Fire Plan, designing an Anchor Stop Device, and providing as-built drawings for a new Kongsberg Sonar System. CMC also supported Bristol Harbor Group in helping to assess upgrading the ship’s propeller.

Deadweight Survey and Stability Test

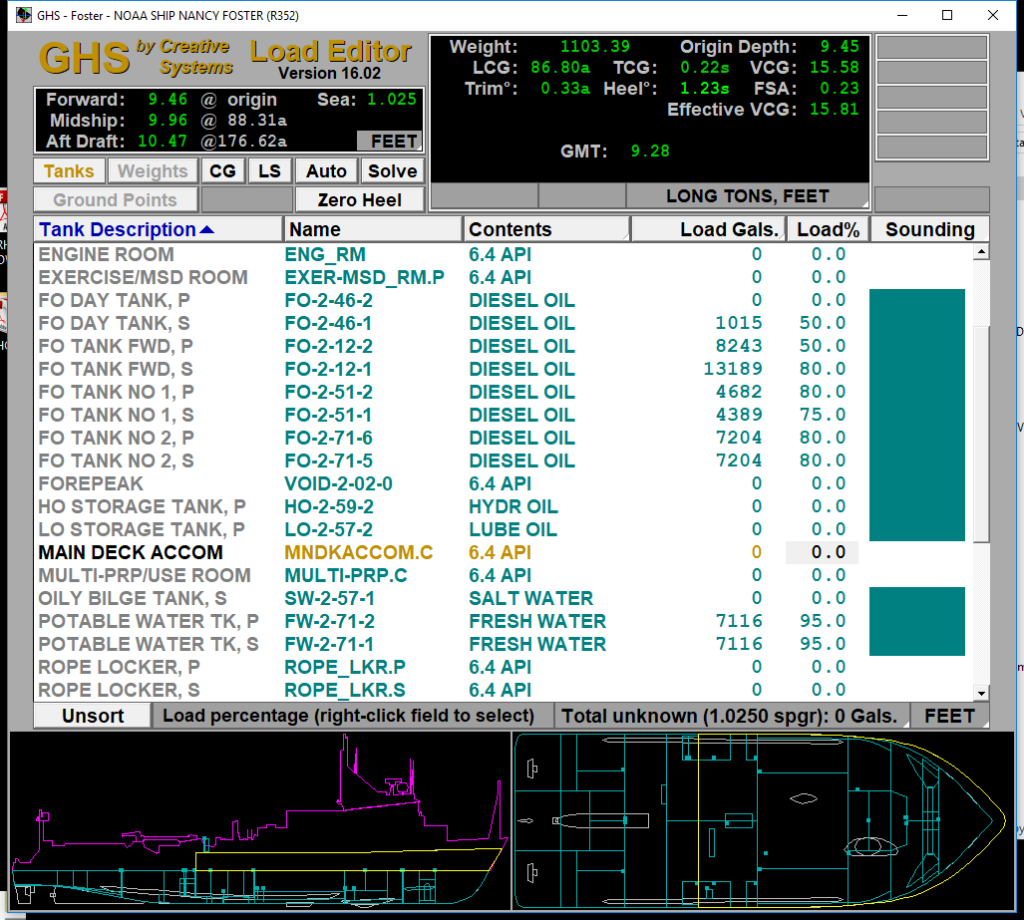

Prior to the Stability Test, CMC was also tasked with performing the necessary calculations to removed ballast lead from one side of the ship in order to remove a list of approximately 0.5 degrees. The Deadweight Survey was conducted over a period of a few weeks while the ship was in drydock.

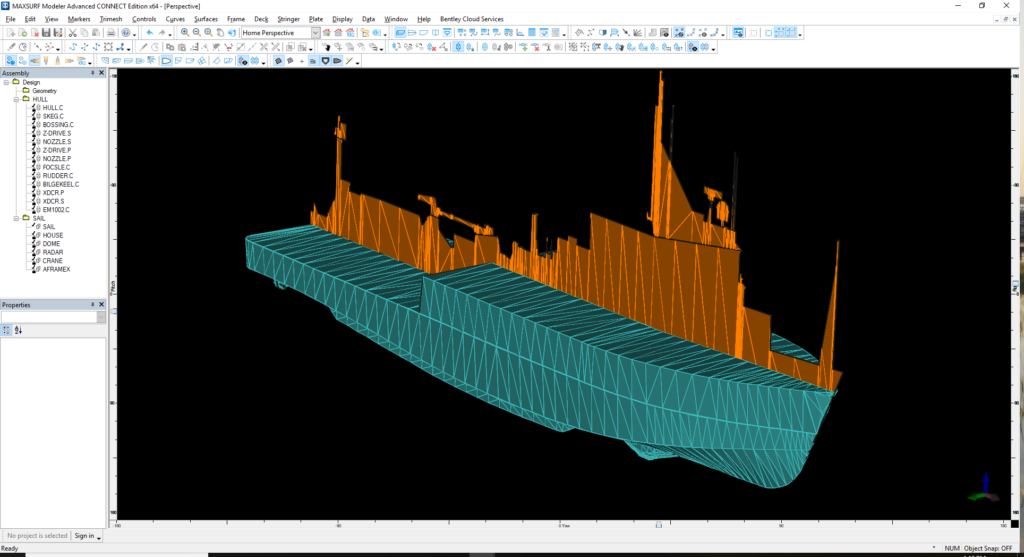

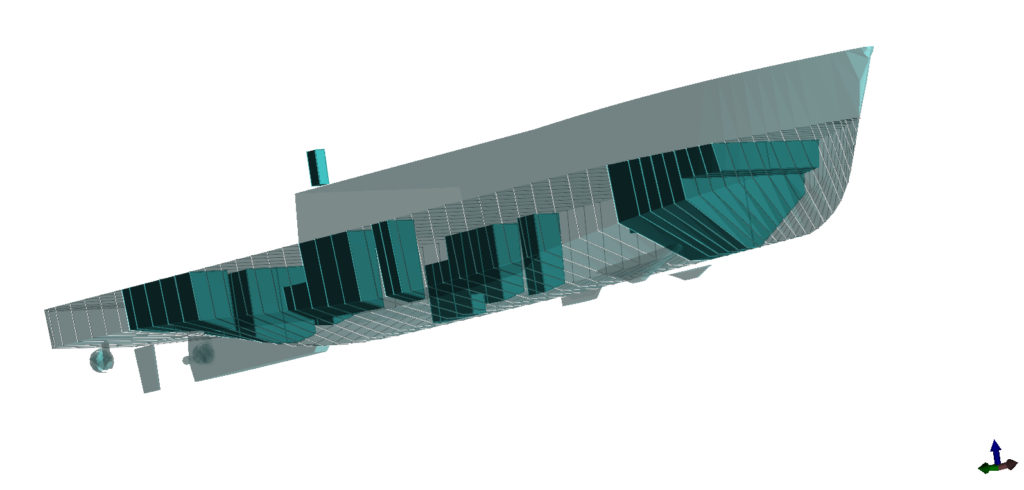

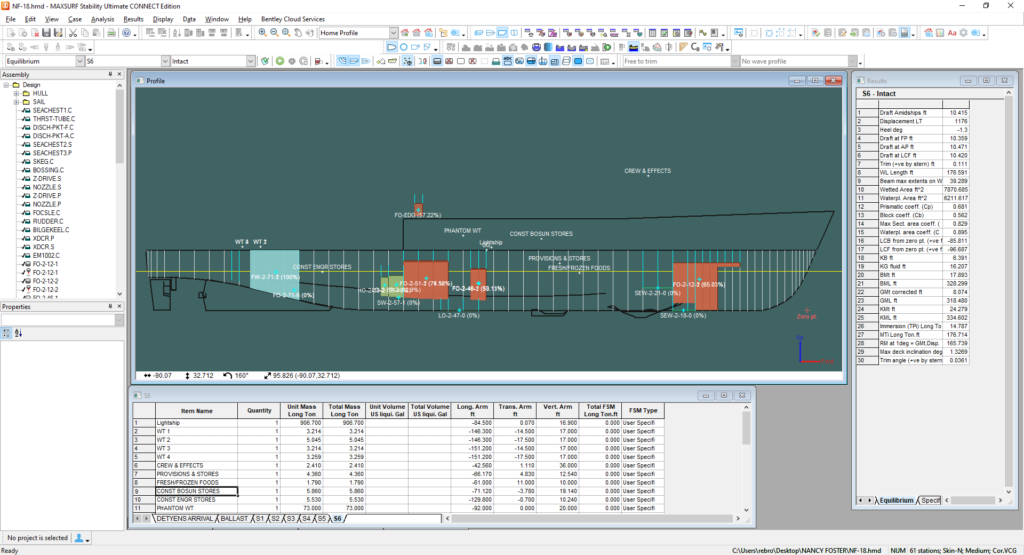

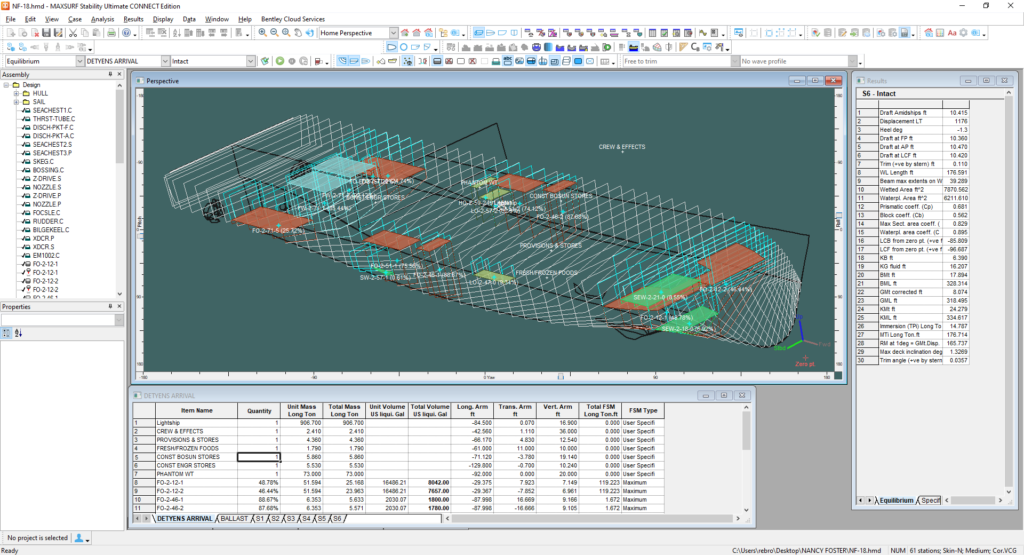

A GHS hydrostatic model used for the original Trim and Stability Booklet was provided by the NOAA Naval Architect, and this was helpful. CMC’s in-house stability software is MAXSURF, and fortunately, the GHS model file can be easily imported into MAXSURF showing all of the hull, tank, and compartment geometry with a high degree of accuracy to ensure excellent correlation and results.

CMC developed the shipyard’s procedure for conducting the stability test using available test weights at the shipyard. The test was performed inside of the shipyard’s graving dock after conducting the Deadweight Survey with the ABS Surveyors. Before conducting the test however, several tons of ballast lead was removed from one side of the ship in order to “zero in” the list condition. CMC made extensive use of the powerful capabilities of MAXSURF Stability for making all of the required calculations for the removal of lead and shifting of test weights for the stability test.

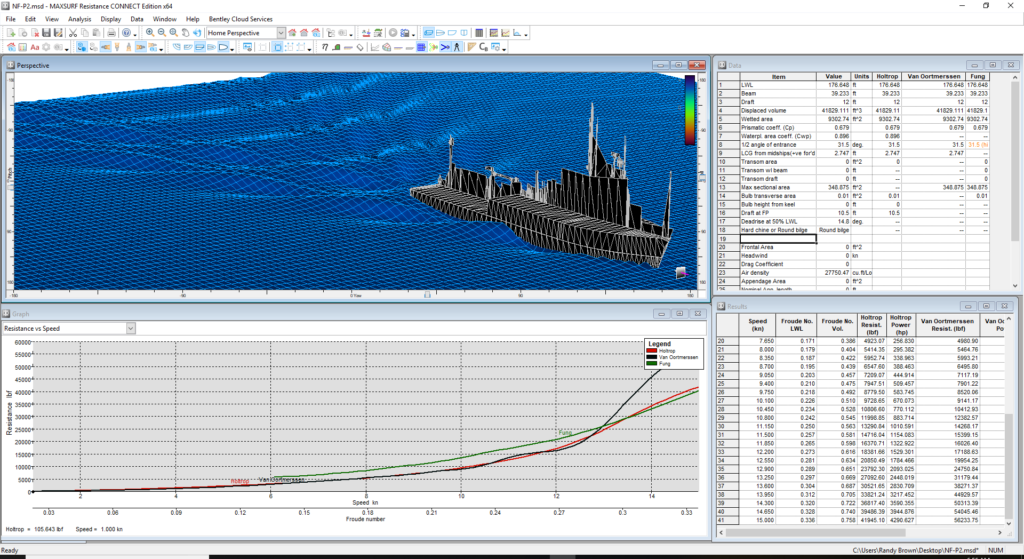

CMC also used MAXSURF Resistance in order to make hull resistance and powering calculations which were utilized by Bristol Harbor Group to perform a propeller upgrade study for NOAA.