Diverse Hands-On Experience

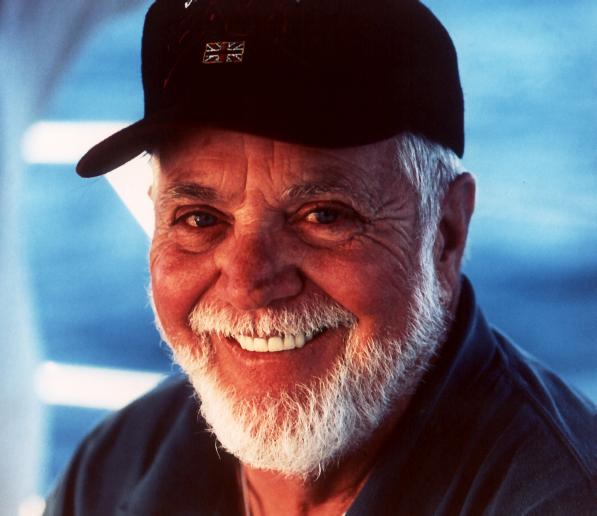

I started Charleston Marine Consulting in late 2014 with a goal to offer the marine industry a diverse mix of consulting services and software solutions that tap into my experience in shipbuilding, manufacturing, program management, and sales. Later in my career, I was able to leverage many years of hands-on experience as a Captain operating both power and sailing vessels.

Up until November 2022, our South Carolina based company was an authorized Channel Partner (reseller) for Bentley Systems, offering MAXSURF Naval Architecture software solutions to clients in the United States and Canada. In early 2023, I decided to transition into a “semi-retirement” mode in order to pursue my passion for blue water sailing and travelling the world with my wife of 30+ years, Kay. Life is short and I am fortunate to be able to retire at a young age.

For the time being, this web site remains active mainly to inspire young men and women who are contemplating a career as a Naval Architect. Over the years, I have had numerous young folks from high school, college, and the military, reach out to me for some career advice after they spent some time on my web site.

This web page shares some of my story. Looking back, I have no regrets, only great memories of my working life as a Paper Boy, Bus Boy, Dish Washer, Waiter, Yacht Rigger, Engineer, Naval Architect, Sales Executive, Operations VP, Business Owner, and Boat Captain.

My web site is dedicated to my father, Richard D. Brown, who deserves the credit for steering me in the right direction for my career.

The success of CMC would not have been possible without the help and dedication of my wife, Kay Brown. She supported me in so many ways selling Bentley MAXSURF, performing Deadweight Surveys, Stability Tests, and Weight Control efforts on very large MSC ships. The folks at the shipyard along with ship crew members always enjoyed her smile and upbeat personality.

Let’s Go Back in Time to 1976. Closing My First Sale

At Age 14, I started working on boats, learning a lot of hands-on skills from my Dad. On a hot summer morning in Lake Oswego, Oregon, my Dad asked me to clean up the family’s O’Day 22 sailboat to get it ready to sell before moving the family to the East Coast. At the end of a long day of bottom painting, cleaning, and hull waxing, a Minister with his wife and two kids in the car stopped next to the boat in the driveway while I was hanging the “For Sale” sign. Within an hour, I closed my first sale which included boat launching and sailing lessons to the family on the Columbia River as part of the deal. When my Dad came home from work at the end of the day, he praised me for making the boat look so great, but then asked why there was no For Sale sign. I then showed him the $1,000 earnest money deposit check for the sale, which was 30% more than what the four-year old boat sold for when it was new.

Hard Work Pays Off at Johnson Brother’s Boatyard on the Jersey Shore

At age 16, my first boatyard job in Point Pleasant, NJ was with C&C Charters, a sailboat charter company. My job was to clean and maintain a fleet of cruising sailboats. At the end of my first day on the job, the owner, Mike Landers, gave me a raise from $2.25 to $2.50 per hour after telling me I was the hardest worker he had ever seen. A year later, I became a hands-on Yacht Rigger and mechanic’s helper for two yacht dealerships in the same boatyard that sold Topaz Sportfishing Boats, Albin Trawlers, along with C&C, and Ericson Sailing Yachts.

Helping to work my way through college, I did everything from refinishing teak, scraping, sanding, waxing, and painting hull bottoms to installing navigation electronics, and commissioning engines. It was really hard work, but I enjoyed it and I learned the importance of doing the job right to please the customer.

I also did several yacht deliveries as a young Captain along the U.S. East Coast. The most interesting delivery was sailing a chain-smoking Professional Pool Player and his girlfriend (both with zero sailing experience) on his newly purchased trade-in Catalina 30 from Manasquan, NJ up to New York City. When he paid for the used boat from the dealership, he actually brought in shoe boxes full of cash! He was a nice man. He bought me a great dinner at the world-famous Stage Deli in Manhattan, NY and flew me home on his friend’s private plane.

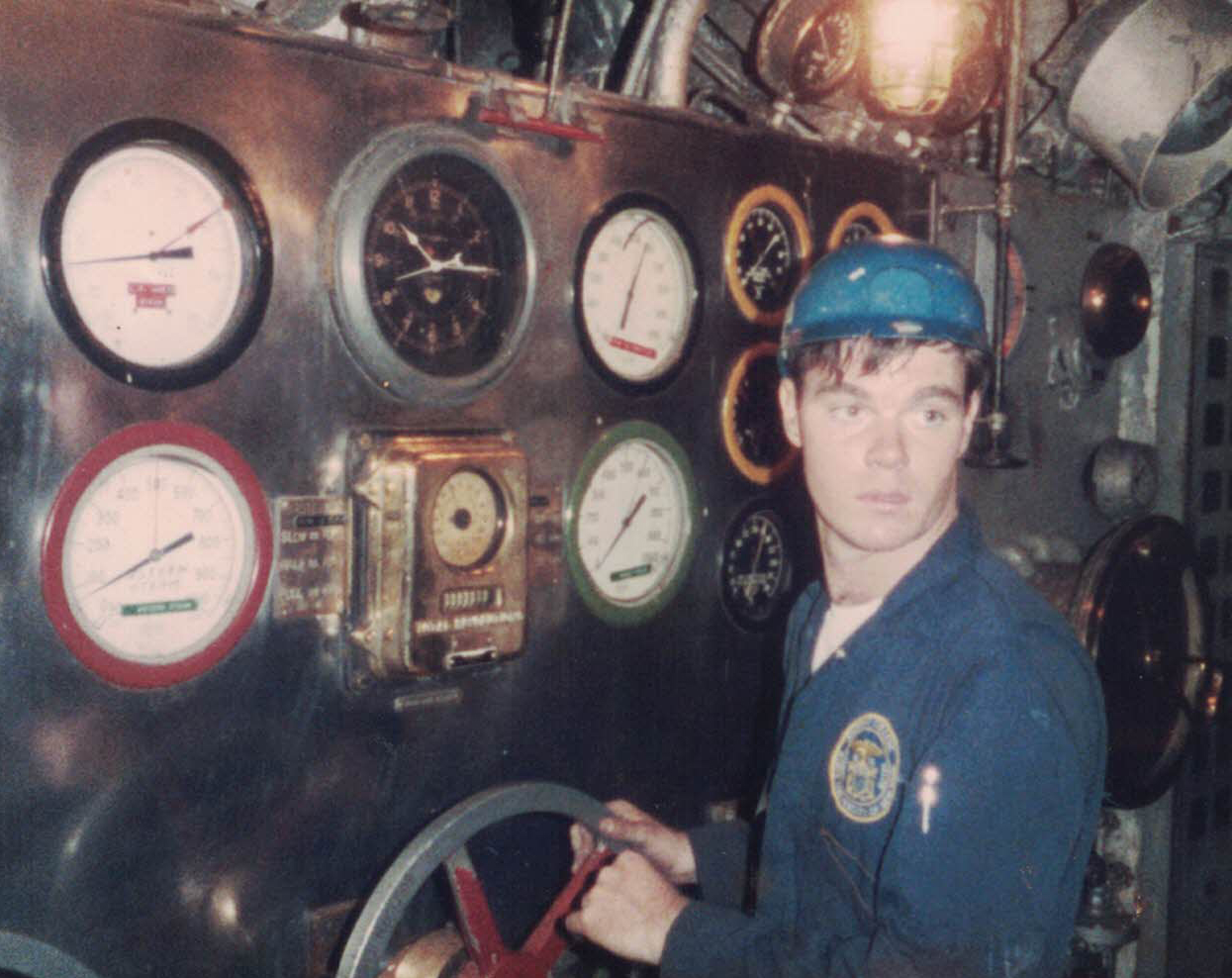

A Hands-On Engineering Education at SUNY Maritime College

In 1985, I graduated with honors from the State University of New York Maritime College with a Bachelor of Engineering degree in Naval Architecture and a USCG Third Assistant Engineer’s License (Steam and Diesel, Unlimited Horsepower).

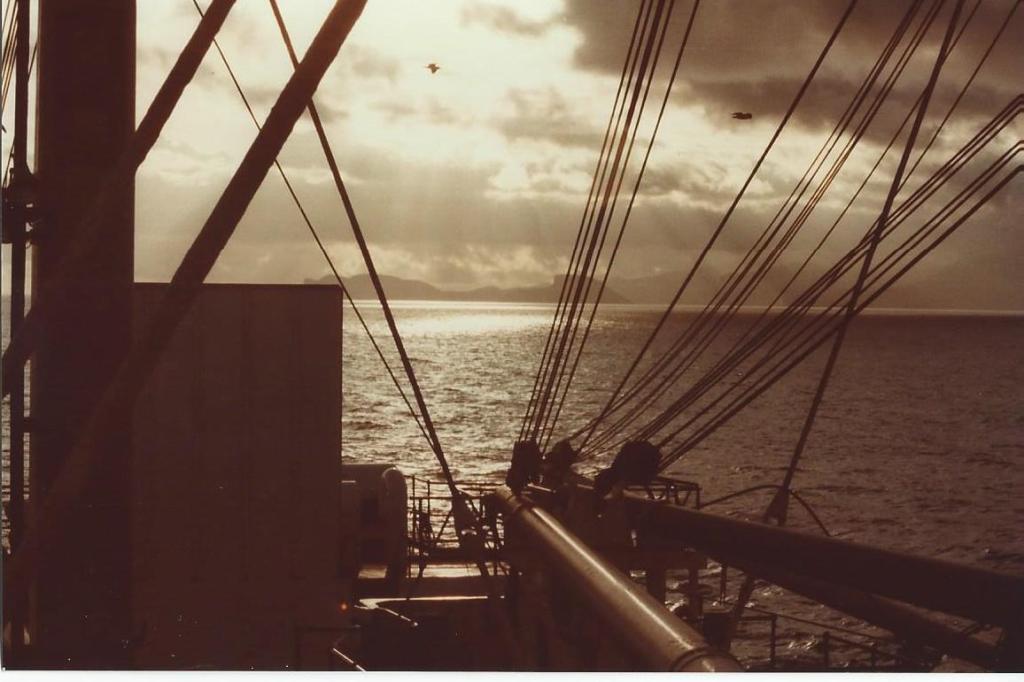

After crossing the Atlantic Ocean six times, visiting nine different European Ports, and spending six months at sea running the 600 psi steam propulsion plant aboard the Training Ship Empire State V, SUNY Maritime College prepared me for a lifelong career in the marine industry as a capable hands-on engineer and Naval Architect.

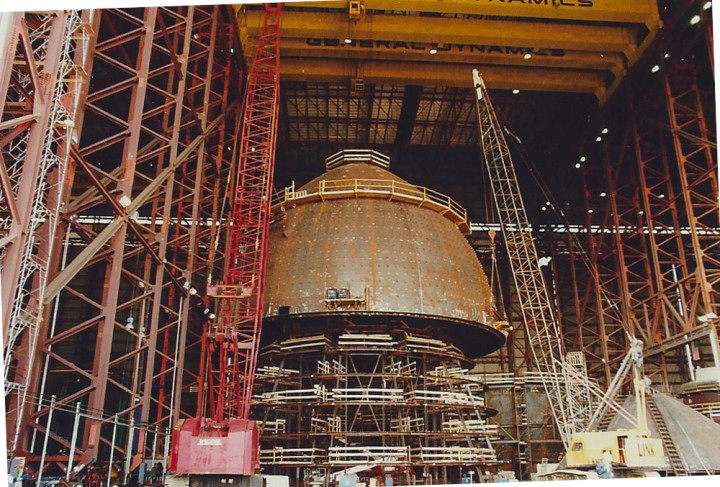

General Dynamics, Electric Boat Corporation

I began my career as a Naval Architect at General Dynamics, Electric Boat Division working there for 11 years on a wide variety of nuclear submarine designs and construction programs. I really enjoyed this job. Highlights of my successful years at “EB” included:

- Winning an award for leading the development, detailed design, testing, and installation of the first all composite and syntactic foam sonar eyebrow for the improved Los Angeles Class Attack Submarines outfitted with under-ice and vertical launch cruise missile capabilities. The first ship outfitted with the “Syntactic Eyebrow” was the USS Pasadena, SSN752, pictured below. The syntactic eyebrow was installed on 21 submarines in the class, and it quickly became a key enabler for the strategically deployed submarines to fulfill their missions anywhere in the world without compromising the weapons load.

I developed expertise in Construction Engineering at the General Dynamics Charleston, SC Manufacturing Facility. In Charleston, large Ohio Class and Los Angeles Class submarine components in excess of 400 tons, such as the submarine Bow, and Stern Ballast Tank Hull Modules, were built, tested, and delivered to the main Shipyard in Groton, CT. As the Construction Engineering Representative from headquarters, I was responsible for evaluating any non-conformance issues, designing the deck layout and approving the final securing of multi-million dollar submarine units on Deck Barges leaving the Charleston Facility on their way to Electric Boat in Groton, Connecticut.

I managed the manufacturing engineering and delivery plan for the construction of 140′ tall, 84′ diameter, 3 million gallon Egg-shaped “Digester Tanks” in Charleston, South Carolina for the City of Boston’s Deer Island Sewage Treatment Plant. The unstiffened steel plate Digester Tanks were enormous in size, having compound curvature (just like an egg), weighing 700 tons each. Randy was also assigned as the responsible on-site engineer for the delivery of the first two tanks in Boston. The General Dynamics “Hercules” Heavy Deck Barge was used for the delivery of the eight tanks for the project. A 1,200 ton Lampson Transi-Lift Crane with a 260 foot boom was used for the offloading and setting of the tanks on their concrete ring wall foundations. The Prime Contractor for the project was Perini Construction.

I managed systems integration of the Virginia Class attack submarine with the Deep Submergence Rescue Vehicle (DSRV) and Advanced Seal Delivery System (ASDS)

Career Shift from Engineering to Software Sales

For a period of 12 years after General Dynamics, I had a successful career in software sales, helping military, aerospace, shipbuilding, and many Fortune 500 customers streamline engineering and improve time to market with Finite Element Analysis (FEA) and Computer Aided Engineering (CAE) tools, working for MSC Software Corporation. In the last six years of my sales career, I was a Senior Account Executive for EMC Corporation, selling EMC Documentum Information Rights Management security software to the United States government intelligence community. I had a security clearance, and my customers included the CIA, NSA, DOD, FBI, DOE, and the State Department along with a number of commercial clients. I really enjoyed software sales as it introduced me to many Fortune 500 companies, senior executives, and government agencies. It also allowed me to travel all over the United States.

Applying the Engineering, Shipbuilding, and Sales Experience

Just before starting CMC, I was Vice President of Operations for three years and prior to that the Director of Business Development and Engineering for four years with Metal Trades Incorporated, a family owned company specializing in Heavy Steel Fabrication, Barge Construction, and Ship Repair.

During my seven years at Metal Trades, I did a bit of everything: Naval Architecture, Engineering Support, a couple of Deck Barge Designs, Barge Cost Estimating and Bids, Formal Proposals for Barges and Tug Boats, Sales, Marketing (New Brochure and Web Site including all Photography), Program Management of all New Barge Construction, and Business Development. During my last three years, I also served as Metal Trades’ VP of Operations. Yes, I wore a lot of hats, but I did enjoy it and I never got bored.

As a member of senior management at Metal Trades, I led the company’s successful entry into new and larger barge construction, handling the marketing, sales, and program management for the construction of more than 14 barges and over $40M in new business with customers that included the U.S. Navy, New York City Department of Transportation, Charleston Heavy Lift, Norfolk Dredging, Southern Dredging, Cotrell Contracting, Yawkey Foundation, and the National Park Service. The barges have been of various types: Deck Barges, Double Hull Fuel Barges, Crane Barges, Floating Dock Barges, a Self-Propelled Shuttle Barge, and even a Swing Bridge on the Intracoastal Waterway. A key contributor to the success of several barge programs was establishing a close partnership with Bristol Harbor Group, Inc.

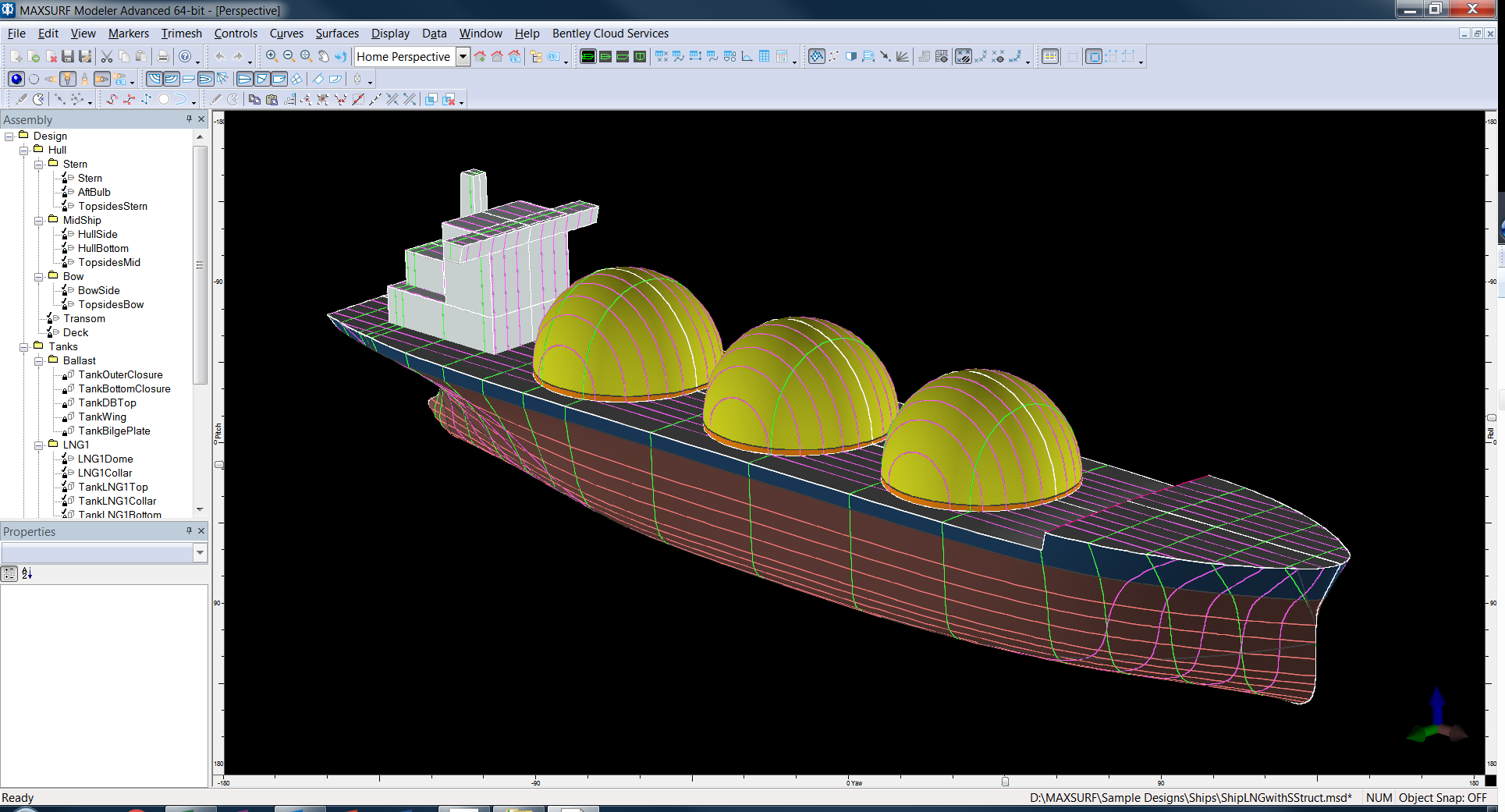

Charleston Marine Consulting – Naval Architecture Support and Bentley Systems Software Offerings

You are invited to read more about us and our past projects on our web site. As a former Bentley Systems Channel Partner for providing MAXSURF, I hope that you enjoy learning more about what this powerful platform has to offer.

One Picture is a Thousand Words

The photo below is the 673 foot strategic sealift ship USNS 2nd Lt John P. Bobo. She is the lead ship of the class (one of five), built by General Dynamics Quincy Shipyard, completed in 1985 (the year I graduated college and began working for GD). When I first learned about these ships being built, little did I know that 35 years later, I would have this story to tell:

- I worked with people involved with designing and building her.

- Metal Trades built most of the gray INLS barges shown on her deck. These barges are part of the temporary floating dock put in place to support the crisis in Gaza, as of this writing.

- I supported three overhauls of the Bobo as a Naval Architect supporting Detyens Shipyard, spending hundreds of hours aboard this ship.

- I (along with my wife, Kay) performed a Deadweight Survey and Stability Test on her as CMC’s last major project, as a result, I was privileged to get to know some of her crew. It was a difficult job (during the Covid Pandemic before the vaccine), but we managed to get through it.

The Meaning of Our Trademarked Logo

The Charleston Marine Consulting Logo is a custom version of the Endless Knot, a symbol for Karma. Another way of putting it, as I would say is “what goes around comes around.” I have always tried my best to treat others the way I would want to be treated, with dignity and respect.

USCG Licensed Captain – Power & Sail – On the East Coast and Caribbean – Thousands of Offshore Miles

I hold a USCG 100 ton Master Merchant Marine Officer License for Motor, Sailing, and Assistance Towing Vessels. I am also a PADI certified Scuba Diver. I have inland and offshore experience as a Captain aboard powered and sailing vessels on the East Coast of the United States, throughout the Caribbean, and most recently, the islands of Greece.

As a professional Boat Captain, I have worked on several different types of vessels in both Charleston and Hilton Head, SC as pictured below.

Some of my favorite photos:

Now you know why I retired…

Please click this link to learn more about experience with Past Projects.

Please click this link to learn more about Qualifications.